Keywords

thermal dilatation, constraint, displacement, structural mechanics, micro-electronics, interconnection matrix

Context / Goal

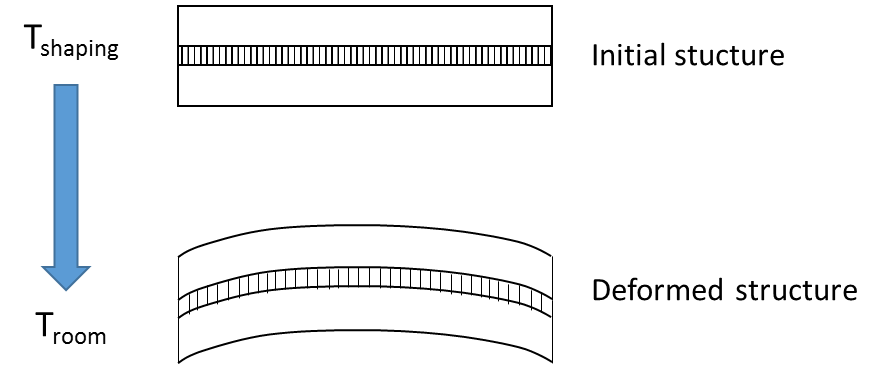

The shaping of some interconnection matrixes for electronic circuits are performed by the assembly of materials at high temperature. The shrinking of the structure induced by the cooling period that follows, leads to the development of stress at the interface between materials which can subsequently break the structure. The displacement, as well as the residual mechanical stress after cooling, must be lowered as much as possible.

This case study is dedicated to the calculation of the thermomechanical stress and strain expected after the assembly of an interconnection matrix with micrometric dimensions. The system studied is composed of two materials, A and B, connected by cylindrical slots lattice, as depicted in the following figure.

SIMTEC's Achievements / Results

The thermomecanical model is developed in stationary condition with Comsol Multiphysics®, with the hypothesis of linear and isotropic elasticity and without initial constraint :

-

Solving for the Hooke’s law, with thermal displacement term.

-

Computation of the stress and displacement induced by the temperature variation ΔT associated with the shaping process.

-

Perfect contacts at the interfaces between materials.

The simulation suggests the following results :

-

The Von Mises stresses are calculated at the interconnections. They are mostly concentrated at the interfaces between materials A and B and the interconnection plots.

-

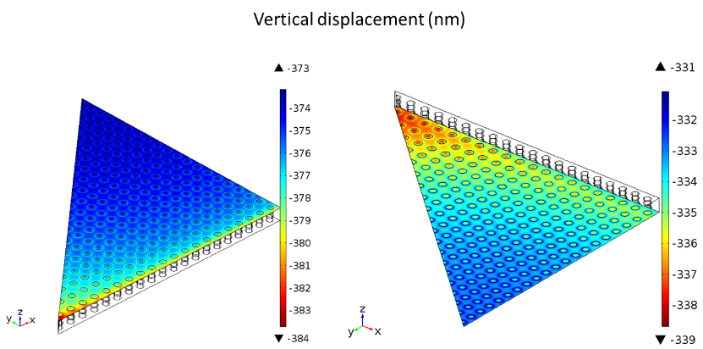

The vertical displacements of the structure induced by the shrinking of materials are computed on the interface between slots and material A or B. It can be noted that the displacement is quite homogeneous over the entire plane. Deviation between maximum and minimum displacement will determine the propensity of the assembly to break.

This model was applied to different types of assemblies, differing from each other by the shape of the interconnecting plots and by the materials involved. The less constrained and deformed assembly, which is the one that is least likely to break, has been selected.